The Optimal Size for a Mechanical Room: Ensuring Efficiency & Safety

- Understanding the Importance of Mechanical Room Size for Efficiency

- Key Factors to Consider When Determining the Optimal Size for a Mechanical Room

- How the Right Mechanical Room Dimensions Enhance Safety Standards

- Common Mistakes to Avoid When Sizing Your Mechanical Room

- Best Practices for Designing a Mechanical Room that Maximizes Efficiency and Safety

Understanding the Importance of Mechanical Room Size for Efficiency

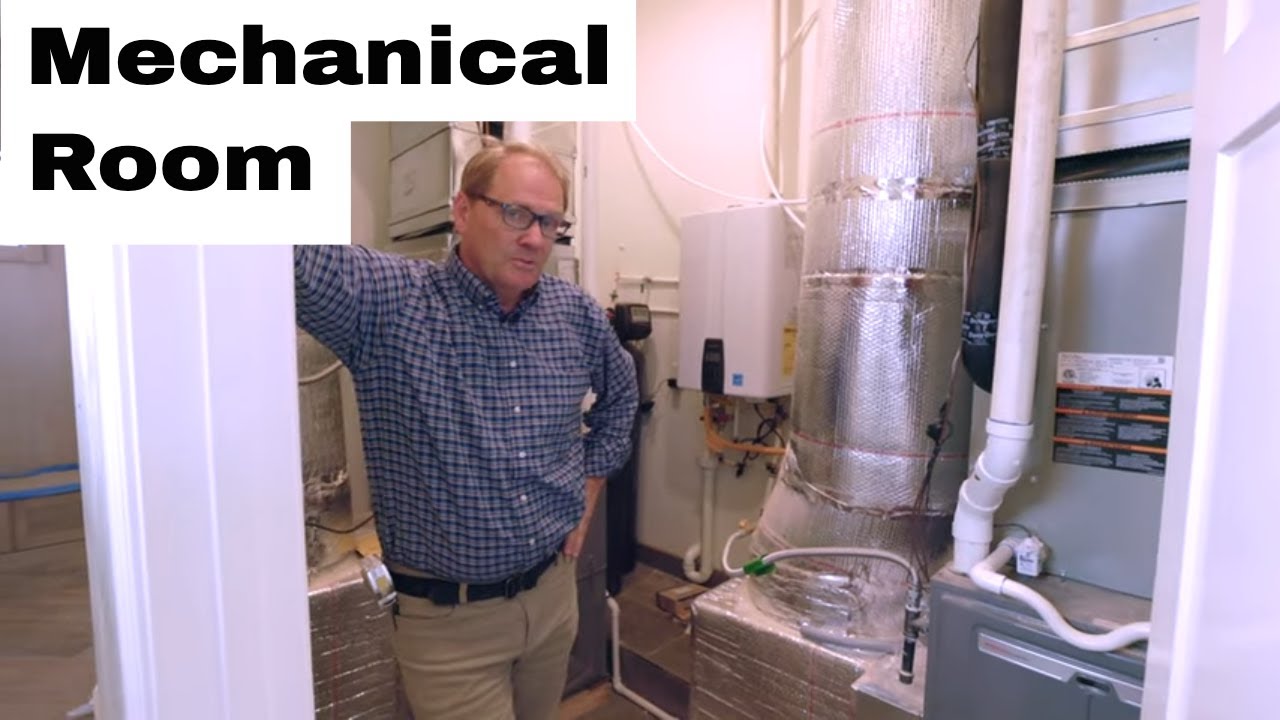

Understanding the size of a mechanical room is crucial for ensuring the overall efficiency of a buildings systems. A mechanical room that is too small can lead to a multitude of issues, including insufficient airflow, increased energy consumption, and difficulty in maintenance and repairs. When the mechanical room is cramped, it can hinder the performance of heating, ventilation, and air conditioning (HVAC) systems, resulting in higher operational costs and decreased comfort levels within the building.

Key Factors Influencing Mechanical Room Size:

- Equipment Dimensions: The size and layout of mechanical equipment, such as boilers, chillers, and pumps, dictate the minimum space required.

- Access and Maintenance: Adequate space is necessary for technicians to access equipment for routine maintenance and emergency repairs.

- Airflow Requirements: Proper airflow is essential for the efficient operation of HVAC systems; insufficient space can restrict airflow and reduce system performance.

- Future Expansion: Planning for future upgrades or additional equipment can prevent costly renovations later on.

The layout of the mechanical room should also take into account the specific needs of the equipment being housed. For example, equipment that generates significant heat may require additional clearance for ventilation and cooling. Additionally, the arrangement of components should facilitate smooth workflow and reduce the risk of accidents. By providing enough space for each piece of equipment, building owners can ensure that their systems operate at peak efficiency.

Moreover, a well-sized mechanical room contributes to the longevity of the equipment. Overcrowded spaces can lead to overheating and increased wear and tear on machinery, ultimately resulting in more frequent breakdowns and costly repairs. By investing in an appropriately sized mechanical room, property managers can enhance operational efficiency, reduce energy consumption, and extend the lifespan of vital systems.

Key Factors to Consider When Determining the Optimal Size for a Mechanical Room

When planning a mechanical room, several key factors must be considered to determine the optimal size that meets both current and future needs. First and foremost, equipment size and type play a critical role. Different mechanical systems, such as HVAC units, boilers, and pumps, require varying amounts of space not only for installation but also for maintenance and operation. Assessing the dimensions and specifications of the equipment you intend to install will provide a clearer picture of the necessary room size.

Another important consideration is accessibility. A mechanical room must allow easy access to all equipment for routine maintenance, repairs, and inspections. This means not only accounting for the footprint of the equipment but also ensuring there is adequate clearance around each unit. The National Fire Protection Association (NFPA) recommends maintaining specific clearances to ensure safety and efficiency. Incorporating these accessibility requirements into your design will prevent future complications and enhance the longevity of the equipment.

Future expansion is also a vital factor to keep in mind. As technology evolves and energy efficiency standards become more stringent, there may be a need to upgrade or expand your mechanical systems. Planning for potential growth by allocating extra space can save time and costs in the long run. Its wise to consult with engineers or contractors to anticipate future needs based on the intended use of the building and any foreseeable changes in mechanical requirements.

Lastly, consider the local building codes and regulations that may dictate specific size requirements for mechanical rooms. Different jurisdictions have various guidelines regarding ventilation, fire safety, and energy efficiency that can impact the design and size of your mechanical room. Understanding these regulations will ensure compliance and avoid potential legal issues during and after construction. Taking all these factors into account will lead to a well-planned mechanical room that meets your operational needs effectively.

How the Right Mechanical Room Dimensions Enhance Safety Standards

The dimensions of a mechanical room play a crucial role in ensuring safety standards are met and maintained. Adequate space allows for proper installation and maintenance of mechanical systems, reducing the risk of accidents and operational failures. A well-designed mechanical room can help facilitate safe access to equipment, promote efficient airflow, and minimize hazards associated with mechanical operations.

Space for Equipment and Personnel

When determining the appropriate dimensions for a mechanical room, it is essential to consider the following factors:

- Clearance Requirements: Equipment such as boilers, pumps, and HVAC systems require specific clearances for safe operation and maintenance. Insufficient space can lead to overheating, increased wear, and safety risks.

- Access for Maintenance: Ample room ensures that technicians can safely access and service equipment without the risk of injury. This is particularly important in emergencies when quick access is vital.

- Emergency Egress: The layout should allow for safe evacuation routes in case of emergencies, such as leaks or equipment failures. Proper dimensions can help prevent bottlenecks during an evacuation.

Ventilation and Air Quality

Another critical aspect of mechanical room dimensions is the ability to maintain proper ventilation and air quality. Adequate space allows for the installation of ventilation systems that ensure a steady flow of fresh air, reducing the risk of hazardous fumes accumulating. This is particularly important in rooms housing equipment that generates heat or exhaust.

By incorporating the right dimensions into the design of mechanical rooms, facility managers can significantly enhance safety standards, providing a secure environment for both personnel and equipment.

Common Mistakes to Avoid When Sizing Your Mechanical Room

When it comes to designing a mechanical room, avoiding common pitfalls can significantly impact both functionality and efficiency. One frequent mistake is underestimating the space required for equipment. Many individuals make the error of fitting equipment into a space that seems adequate without accounting for maintenance access, ventilation, and future expansion. A cramped mechanical room can lead to operational inefficiencies and increased maintenance costs.

Another common oversight is neglecting to consider the placement of ductwork and piping. Poor planning can result in a layout that complicates installation and maintenance. Ensuring that ductwork and piping are strategically placed not only enhances airflow and efficiency but also makes it easier for technicians to perform necessary repairs and upgrades. It is essential to create a comprehensive layout that includes all mechanical systems and their connections.

Furthermore, failing to plan for adequate ventilation is a critical mistake. Mechanical rooms often house equipment that generates heat, and without proper ventilation, temperatures can rise, leading to equipment failure. It’s vital to incorporate ventilation systems that allow for adequate air circulation, ensuring that the mechanical room remains at optimal operating conditions. This consideration is especially important in smaller spaces where heat buildup can be more pronounced.

Lastly, overlooking local building codes and regulations can lead to significant issues down the line. Each jurisdiction has specific requirements regarding mechanical room design, including space, accessibility, and safety measures. Ignoring these codes can result in costly rework or even fines. Always consult with local authorities and ensure that your mechanical room meets all legal requirements before proceeding with construction.

Best Practices for Designing a Mechanical Room that Maximizes Efficiency and Safety

Designing a mechanical room requires a careful balance of efficiency and safety to ensure optimal performance and compliance with regulations. To achieve this, it is essential to consider several best practices that can significantly enhance both aspects. One of the primary considerations is the layout of the room. A well-organized space allows for easy access to equipment, which not only improves operational efficiency but also enhances safety by minimizing the risk of accidents during maintenance or repairs. Equipment should be arranged in a logical sequence based on workflow, and there should be ample space around each unit to facilitate safe movement.

Another critical aspect of mechanical room design is ventilation. Proper ventilation is necessary to maintain a safe environment, especially in spaces housing boilers, generators, or other equipment that may emit harmful gases. Implementing adequate exhaust systems and ensuring that air intakes are unobstructed can help mitigate the risks associated with poor air quality. Additionally, consider incorporating sensors that monitor air quality and alert personnel to any hazardous conditions. This proactive approach not only enhances safety but also contributes to the overall efficiency of the mechanical systems by preventing downtime caused by air quality issues.

Lighting is another essential factor in creating an efficient and safe mechanical room. Adequate lighting helps personnel perform maintenance tasks more effectively and reduces the risk of accidents caused by poor visibility. Utilize energy-efficient LED lighting to reduce operational costs while ensuring that all areas of the room are well-lit. Furthermore, installing motion sensors can help conserve energy by ensuring that lights are only on when the space is occupied.

Lastly, incorporating safety features such as emergency shut-off switches, fire suppression systems, and clearly marked exits can greatly enhance the safety of the mechanical room. Regular safety audits and training for staff on emergency procedures can also foster a culture of safety. By prioritizing these best practices, designers can create a mechanical room that not only operates efficiently but also prioritizes the safety of personnel and equipment.

Did you like this content The Optimal Size for a Mechanical Room: Ensuring Efficiency & Safety See more here General Mechanics.

Leave a Reply